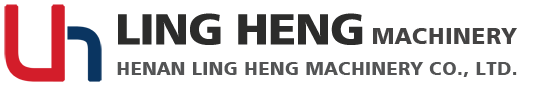

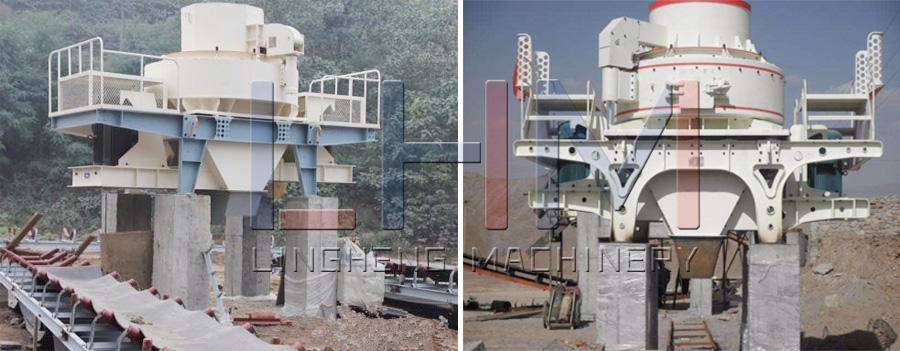

Introduction: On the basis of introducing German technologies on sand-making machines and upgrading the VSI Sand Maker, LHM develops and researches a new generation of sand-making machine--VSI5X Sand Maker. VSI5X Sand Maker has multiple independent property rights and integrates 3 kinds of crushing modes. Now, VSI5X Sand Maker is the core equipment in machine-made sand industry.

Email: [email protected]

WhatsApp: +86 13223066055

On the basis of introducing German technologies on sand-making machines and upgrading the VSI Sand Maker, LHM develops and researches a new generation of sand-making machine--VSI5X Sand Maker. VSI5X Sand Maker has multiple independent property rights and integrates 3 kinds of crushing modes. Now, VSI5X Sand Maker is the core equipment in machine-made sand industry.

Our Sand Making Machine, also called as VSI5X Vertical-shaft Impact CrusherVSI5X, is an advanced new product. It has the advantages of lower maintenance costs, longer service life of vulnerable parts, quicker adjustments.

5X sand making machine is widely used in various metallic and nonmetallic ores, cement, corhart, abrasive material, glass, construction material, machine-made sand, metallurgy, etc. It is also applicable to crush various stones with different hardness in medium and fine crushing area, such as iron ore, non ferrous metal, emery, bauxite, quartz sand, basalt, etc.

Features of VSI5X Sand Making Machine

1. Rotor with deep chamber increases 30% capacity after perfect design.

2. Side plate direction can be changed to increase material utility ratio, operating ratio can be increased 48%.

3. Worn hammer with combined type is only changed to reduce operating cost 30%. Another pair of vice hammer is added to prevent from damaging main hammer and side plate.

4. The most key wear resistant material uses wear resistant and high temperature resistant material in American important area.

5. Rhombus shape impact plate is used to prevent side plate from being damaged.

6. Bearing is famous international brand imported from Japan, Sweden, America, etc.

7. Perfect discharge and smooth curve reduce resisting force when material flows, so capacity is increased greatly.

8. Spread dish with double purposes can make two feeding ways change easily.

9. Special seal structure under main shaft guarantee no oil leak without seal.

10. Japanese hydraulic opening cover device is originally imported. The cover is moved easily and inspection of inner part is easy.

11. Motor with high grade of protection is selected. The motor has features of high efficiency, low noise, etc. The motor complies with IEC, insulation grade F, protection grade IP54/55.

The Working Principle of VSI5X Sand Making Machine

VSI5X Sand Maker has two feed modes-"feed at center" and "feed at center & sides". As for the former mode "feed at center", materials at the feed hopper firstly pass through the central hole into the high-speed spinning rotor. In the rotor, materials are fully accelerated and thrown outwards from the launching port to collide with a part of materials that freely fall after rebound. Next, materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening. As for the latter mode "feed at center & sides", firstly, materials at the feed hopper pass through the circular hole. Then, materials are divided into two parts by the distributing tray. One part of materials enter the high-speed rotating impeller while the other part of materials fall from all sides of the tray. Materials in the impeller would be accelerated rapidly and thrown outwards at a high speed to collide with materials falling from all sides of the tray. Next, all materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening.

Technical Data of VSI5X Sand Maker

| model | VSI5X7615 | VSI5X8522 | VSI5X9532 | VSI5X1145 | |

| Throughput capacity (t/h) | Center and Ring feeding | 150-280 | 240-380 | 350-540 | 500-640 |

| Center feeding | 70-140 | 120-190 | 180-280 | 250-360 | |

| Max. Feed Size (mm) | Soft material | <35 | <40 | <45 | <50 |

| Hard material | <30 | <35 | <40 | <45 | |

| Rotation speed (r/min) | 1700-1900 | 1500-1700 | 1300-1510 | 1100-1310 | |

| Power of double motor (KW) | 150 | 220 | 320 | 440 | |

| Overall dimension L*W*H (mm) | 4100*2330*2300 | 4140*2500*2700 | 4560*2600*2900 | 5000*2790*3320 | |

| Weight (t) | 8.6 | 11.8 | 17.5 | 27.5 | |

| Power source | 380v,50Hz | ||||

| Thin oil lubrication station | Power for double oil pump | 2*0.37 KW | |||

| Safety | To make sure the supply of oil with double oil pump, working without oil, temperature when water cools, start the motor by heating it in winter. | ||||

| Overall dimension L*W*H (mm) | 820*520*1270 | ||||

| Power for oil box heater | 2 KW | ||||

Note: Capacity depends on crushing limestone, material size, moisture and features also affect capacity. The bulk specific weight is calculated by 1.6t/m³. When the width of the feeding port is above 600mm, it is a large-scale machine while when the width ranges from 300 to 600mm, it is a medium-sized machine.

Lubricating System Parameter

| Oil box volume (L) | 240 |

| Rated pressure (MPa) | 0.63 |

| Flow capacity (L/min) | 8 |

| Power (KW) | 0.31 |

| Cooling water consumption (m3/h) | >=1.2 |

| Electrical heating voltage (V) | 220 |

| Medium | Bearing oil 32-46# |

Note: Any change of technical data shall not be advised additionally.