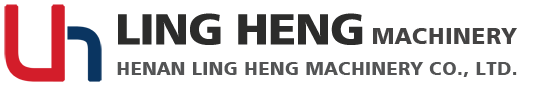

Introduction: Raymond Mill is applicable to the grinding and processing of more than 280 kinds of non-flammable and non-explosive materials with hardness less than 7 and humidity less than 6% in mining, construction, chemical industry and metallurgy, such as stone flour, barite, bentonite, calcium carbonate, clinker, coal, dolomite, lead xide, limestone, marble, quartz, ultrafine.

Email: [email protected]

WhatsApp: +86 13223066055

Raymond Mill is applicable to the grinding and processing of more than 280 kinds of non-flammable and non-explosive materials with hardness less than 7 and humidity less than 6% in mining, construction, chemical industry and metallurgy, such as stone flour, barite, bentonite, calcium carbonate, clinker, coal, dolomite, lead xide, limestone, marble, quartz, ultrafine.

The fineness of the finished product can be adjusted from 100 meshes to 325 meshes according to requirements. Raymond mill is the main and widely used grinding machine.

After many years of practice and improvement, its structure is getting perfect day by day. Due to low consumption, low investment, environment friendliness, small occupation area and more efficiency than the traditional mill, Raymond grinding mill is widely used in the field of metallurgy, building materials, chemical industry and mining to process powder.

The whole grinding plant is a vertical structure of systematic characteristic, so it occupies small area. It is an independent production system from crushing of raw material to grinding and packing.

The Main Benefits and Advantages

1. High efficiency, low power consumption, small footprint and one-time low investment.

2. High degree of fineness and uniformity of various finished product powder make the sieve passing rate up to 95%.

3. The adoption of advanced technology effectively reduces dust pollution.

4. Zero-noise mode of operation is standard of the Raymond mill.

5. Main mill transmission device adopts sealed gear box and belt wheel design with smooth transmission and reliable operation.

6. Compared with other grinding equipments, the new model pass rate is up to 99%.

7. Quick-wear parts are made of high manganese steel with long service life. All the motors brands are national standard.

8. The electric control system is integratedly controlled, so the automaticity is high. No people are needed in the operating room.

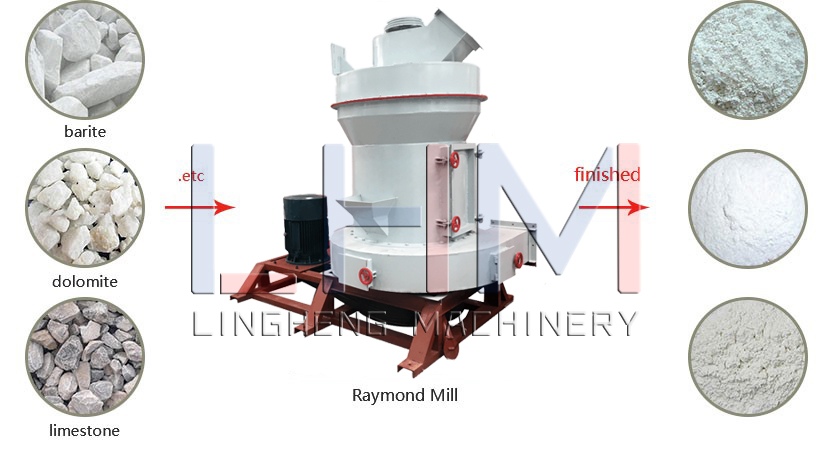

Raymond Mill Grinding Production Line

Material after broken jaw crusher by bucket elevator sent to the storage bin, through the electromagnetic vibrating feeder grinding materials uniform, quantitative, and continuously to the grinding powder main body, after the grinding powder under the action of blower blows the classifier for separation, after the separation of unqualified powder back to grinding, qualified fine powder by the pipe to the storage bin, finally by the discharge valve output is the finished product.

Technical Data of Raymond Mill

| Model | Number Of Grinding Roll | Size Of Grinding Roll(mm) | Diameter and Height of Grinding Ring(mm) | Max.Feeding size(mm) | Finished Size(mm) | Capacity (t/h) | Main Motor Power (kw) | Weight (t) | Dimension (mm) |

| 3R1510 | 3 | 150*100 | 570*100 | 15 | 0.198-0.044 | 0.3-1.2 | 7.5 | 2.0 | 3200*2100*3800 |

| 3R2115 | 3 | 210*150 | 630*150 | 15 | 0.198-0.044 | 0.4-1.6 | 15 | 3.6 | 4100*3300*4500 |

| 3R2615 | 3 | 260*150 | 780*150 | 20 | 0.198-0.044 | 0.8-2.5 | 18.5 | 4.2 | 4300*3500*5100 |

| 3R2715 | 3 | 270*150 | 830*150 | 20 | 0.198-0.044 | 0.9-3 | 22 | 4.8 | 4500*4100*5200 |

| 3R3015 | 3 | 300*150 | 875*150 | 20 | 0.198-0.044 | 1.2-4 | 30 | 5.3 | 4800*4100*5200 |

| 4R3016 | 4 | 300*160 | 890*160 | 20 | 0.198-0.044 | 1.5-4 | 30 | 8.5 | 6500*4100*5200 |

| 4R3216 | 4 | 320*160 | 970*160 | 25 | 0.198-0.044 | 1.8-6 | 37 | 15 | 7900*5800*9100 |

| 5R4119 | 5 | 410*190 | 1280*190 | 30 | 0.198-0.044 | 3-10 | 75 | 24 | 9200*8000*9700 |

Note:Any change of technical data shall not be advised additionally.