Introduction: Lignite Dryer is also known as lignite coal dryer, fly ash dryer or coal powder dryer. Lignite Dryer is a drying machine mainly used for drying lignite coal.The lignite dryer made in Ling Heng not only has reliable quality but also has affordable price.

Email: [email protected]

WhatsApp: +86 13223066055

Lignite Dryer is also known as lignite coal dryer, fly ash dryer, brown coal dryer or coal powder dryer. Lignite Dryer is a drying machine mainly used for drying lignite coal. Traditional drying method adopts centrifugal machine for dehydration, and the equipment is expensive and has low production capacity and small dehydration extend. Generally it can only reduce about 10% of the water and there is still 15%-20% of water content. After the lignite dryer being dried, the water content of the material can be less than 9%. The lignite dryer made in Ling Heng Machinery not only has reliable quality but also has affordable price.

Lignite Rotary Dryer adopts the new technology of first crushing and scattering the lignite coal and drying it with heating power, making the drying disposal of the materials realize continuity, industrialization and automation. The water content of the moist lignite coal processed by brown coal dryer can be reduced from 25%-30% to below 13%, and the moist lignite coal can be used as bunker coal, thus improving the coal washing and dressing technology and having excellent economic, social and environmental benefits.

The Performance Characteristics of Lignite Dryer

1. It reduces land area by 60% than single drum dryer. Thus civil construction investment can be reduced by 60%. This tripe-pass dryer is very easy to be installed.

2. No air-leakage, which solve the problem of sealing.

3. Output material material is lower than 60 centigrade, which is no need to be cooled after drying.

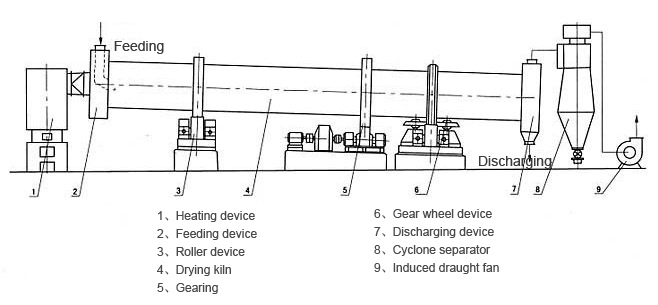

The Principle of Lignite Dryer

Lignite, coal ash and other material are sent into feeder through conveyor belt, and the coal ash is sent into drying roller through the feeder. With the ruffle of uniformly distributed board device in drying roller, the coal ash is evenly contacted with hot air to transfer heat and perfect drying. The dried coal ash is discharged into finished products via shedder in the end of the roller. The dried products are discharged by the belt discharging machine, and the drying process is finished.

Technology Data of Lignite Dryer

| Specification(mm) | Obliquity(%) | Speed(r/min) | Inlet Air Temperature(oC) | Power(KW) | Volume(m³) | Production Capacity(t/h) | Weight(t) |

| ∅600*6000 | 3-5 | 3-8 | <=700 | 3 | 1.69 | 0.5-1.5 | 2.9 |

| ∅800*8000 | 3-5 | 3-8 | <=700 | 4 | 4.01 | 0.8-2.0 | 3.5 |

| ∅800*10000 | 3-5 | 3-8 | <=700 | 4 | 5.02 | 0.8-2.5 | 4.5 |

| ∅1000*10000 | 3-5 | 3-8 | <=700 | 5.5 | 7.85 | 1.0-3.5 | 5.6 |

| ∅1200*10000 | 3-5 | 3-8 | <=700 | 7.5 | 11.30 | 1.8-5 | 14.5 |

| ∅1200*12000 | 3-5 | 3-8 | <=700 | 11 | 13.56 | 2-6 | 14.8 |

| ∅1500*12000 | 3-5 | 2-6 | <=800 | 15 | 21.19 | 3.5- 9 | 17.8 |

| ∅1800*12000 | 3-5 | 2-6 | <=800 | 18 | 30.52 | 5-12 | 25 |

| ∅2200*12000 | 3-5 | 1.5-6 | <=800 | 18.5 | 45.59 | 6-15 | 33 |

| ∅2200*18000 | 3-5 | 1.5-6 | <=800 | 22 | 68.38 | 10-18 | 53.8 |

| ∅2200*20000 | 3-5 | 1.5-6 | <=800 | 30 | 75.98 | 12-20 | 56 |

| ∅2400*20000 | 3-5 | 1.5-5 | <=800 | 37 | 90.43 | 18-30 | 60 |

| ∅3000*20000 | 3-5 | 1.5-5 | <=800 | 55 | 141.3 | 25-35 | 78 |

| ∅3000*25000 | 3-5 | 1.5-5 | <=800 | 75 | 176.6 | 32-40 | 104.9 |