Introduction: LHHC-Z Series Heavy Hammer Crusher belongs to hammer crusher. According to the development of the crushing industry combined with the experimental data of the stone crushing test base, this new type of hammer crusher is suitable for brittle materials. Compressive strength is below 150Mpa. Such as limestone, bluestone, coal gangue, shale, gravel, gneiss, etc.

Email: [email protected]

WhatsApp: +86 13223066055

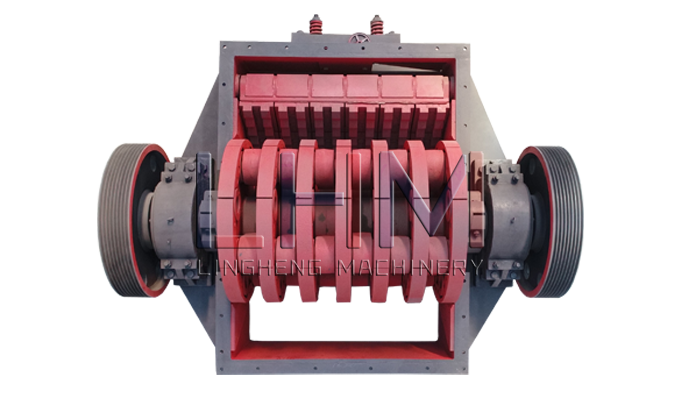

LHHC-Z Series Heavy Hammer Crusher belongs to hammer crusher. According to the development of the crushing industry combined with the experimental data of the stone crushing test base, this new type of hammer crusher is suitable for brittle materials. Compressive strength is below 150Mpa. Such as limestone, bluestone, coal gangue, shale, gravel, gneiss, etc.; feeding size <=1600mm, capacity 150-3000t/h is available. The model has a large feeding size, high crushing ratio and high output. Performance operation is simple and more convenient and the operation is safer and more reliable.

Protruding Advantages of LHHC-Z Series Heavy Hammer Crusher

The details determine the quality and longer service life of rotor core.

1. The vulnerable parts of the rotor disk are all equipped with

wear-resistant retaining rings. The bolts are uniformly made of high-strength

bolts with yield strength of 640MPA of 10.9 and a tensile strength of 800MPA.

They are wear-resistant and impact-resistant and easy to replace and

maintain.

2. The hammer plate is designed with eight-way hammer shaft hole and four-way

spare. The hammer shaft hole is embedded with tungsten alloy steel bush sleeve

which greatly prolongs the life of the rotor disk.

3. The pulley and the main shaft are connected by the expansion sleeve which

is more anti-slip than the traditional key connection.

4. The hammer head can be rotated to 360 degrees around the shaft to avoid

direct impact with the spacer sleeve. It's not easy to break during the head

turning process.

5. Hammerhead production has a modern casting workshop and spectrum analyzer

using the most advanced composite hammerhead. The hammer handle is impact

resistant while the hammerhead is wear resistant.

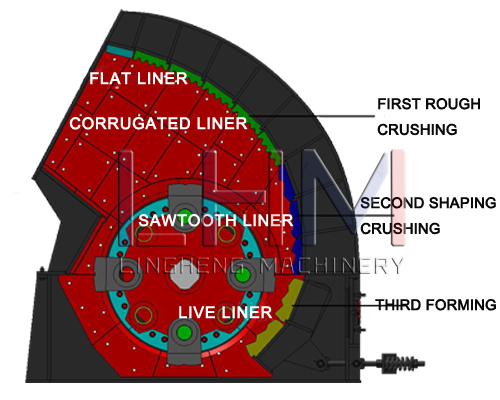

No raft design, low powder rate, more environmentally friendly.

Compared with the traditional hammer breaking the new high-resistance adopts the unique flawless strip design, by adjusting the distance between the active counterattack plate and the rotary track circle on the rotor. While the size of the discharge granularity adjusted the powder extraction rate and the dust is greatly reduced. At the same time the wet material can be broken and the rain does not affect the production which solves the problem that the traditional hammer breaks easily and the output is low.

4 kinds of counterattacks, 3 sections broken, perfect shape.

Curved casing, through the rib structure counter-attack the plate goose egg silk is fixed in the side lining plate (10.9-square square fixed) the casing is firm and not easy to deform. The internal counterattack plate uses 4 different linings: flat lining, corrugated lining, serrated lining and live lining. The flat lining plate is in the position of the machine mouth and the large material enters the crusher mouth to have a large impact force which effectively protects the casing. The crushing zone adopts a corrugated lining plate and the shaping zone adopts a serrated lining to shape the stone. The forming zone adopts a living lining plate which has a self-flow design and perfect grain shape to avoid repeated crushing and achieve automatic discharge of the granular shape.

Technical Data Of LHHC-Z Series Heavy Hammer Crusher

| Model | Rotor Diameter*Length(mm) | Feed Opening Size W*L(mm) | Feeding Size(mm) | Capacity(t/h) | Motor power(kw) | Dimensions(mm) |

| LHHC-Z1310 | 1310*1050 | 890*1075 | <=650 | 150-180 | 160 | 2950*2250*2495 |

| LHHC-Z1512 | 1500*1160 | 1200*900 | <=750 | 250-320 | 160*2 | 3260*2624*2750 |

| LHHC-Z1615 | 1650*1452 | 1500*1200 | <=1000 | 420-500 | 200*2 | 3667*2937*3436 |

| LHHC-Z1815 | 1850*1520 | 1500*1350 | <=1200 | 600-800 | 250*2 | 3680*2915*3515 |

| LHHC-Z1620 | 1660*1900 | 2000*1200 | <=1200 | 800-1000 | 400*2 | 3667*3200*3436 |

| LHHC-Z1820 | 1800*1964 | 2000*1200 | <=1200 | 1000-1200 | 450*2 | 3700*3270*3515 |

| LHHC-Z2225 | 2200*2485 | 2530*1560 | <=1600 | 1800-3000 | 1250 | 4455*4565*4670 |